_Technological Innovation State-of-the-art technology

at the service of design

at the service of design

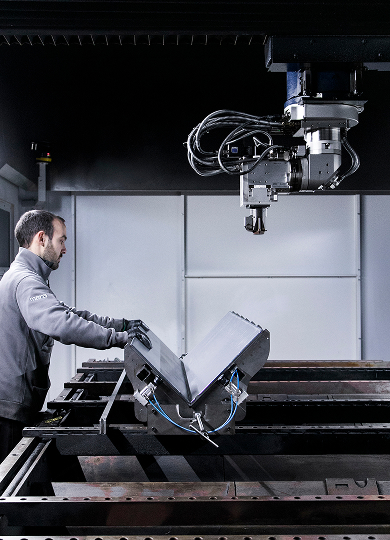

We integrate state-of-the-art, technologically advanced machinery into our production, capable of shaping increasingly innovative projects that are appreciated and recognized internationally and guarantee competitiveness in the market.

The state-of-the-art machinery installed in the company, in addition to improving the quality of the products and optimizing the times, allow the design and mass production of increasingly innovative and technological articles.

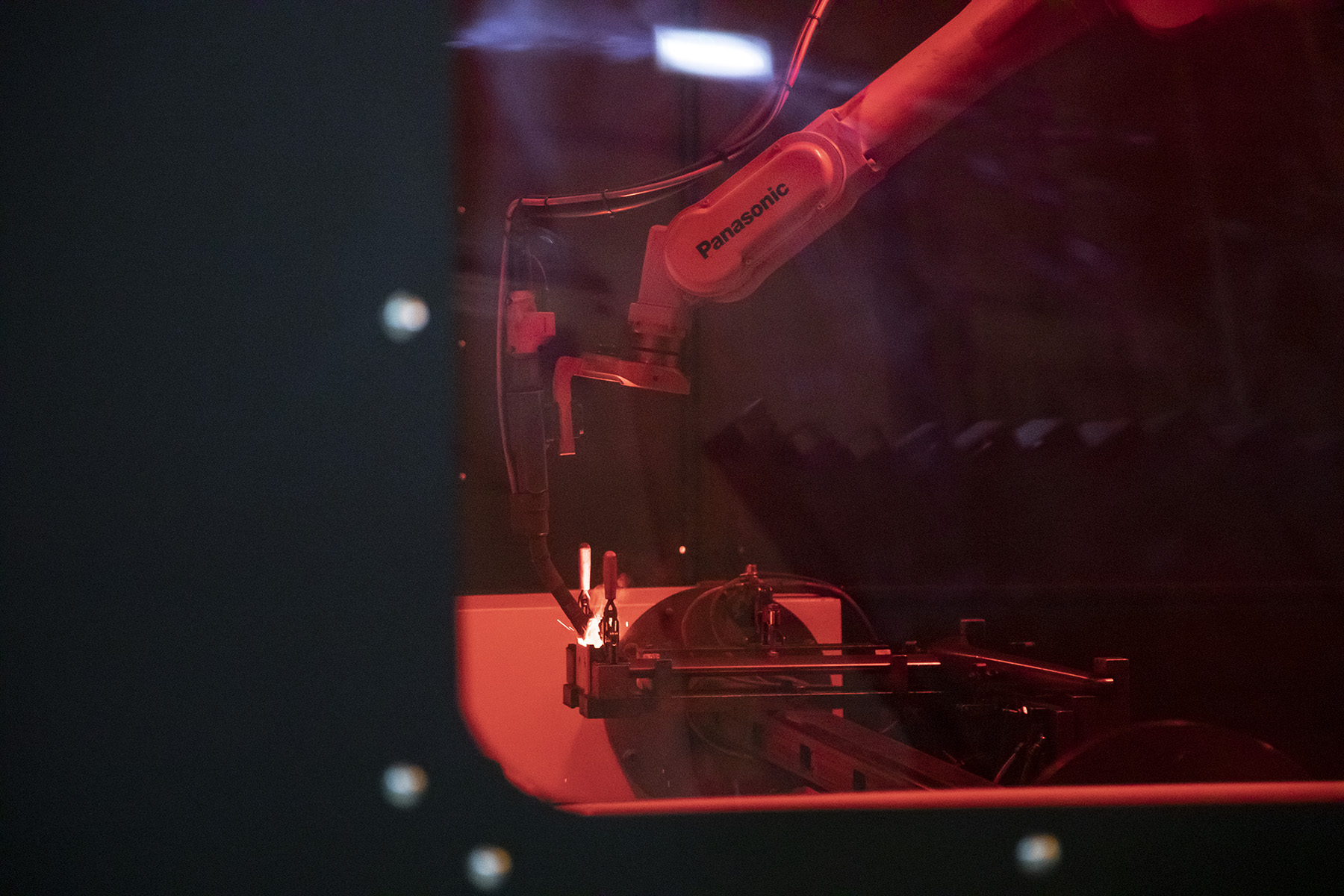

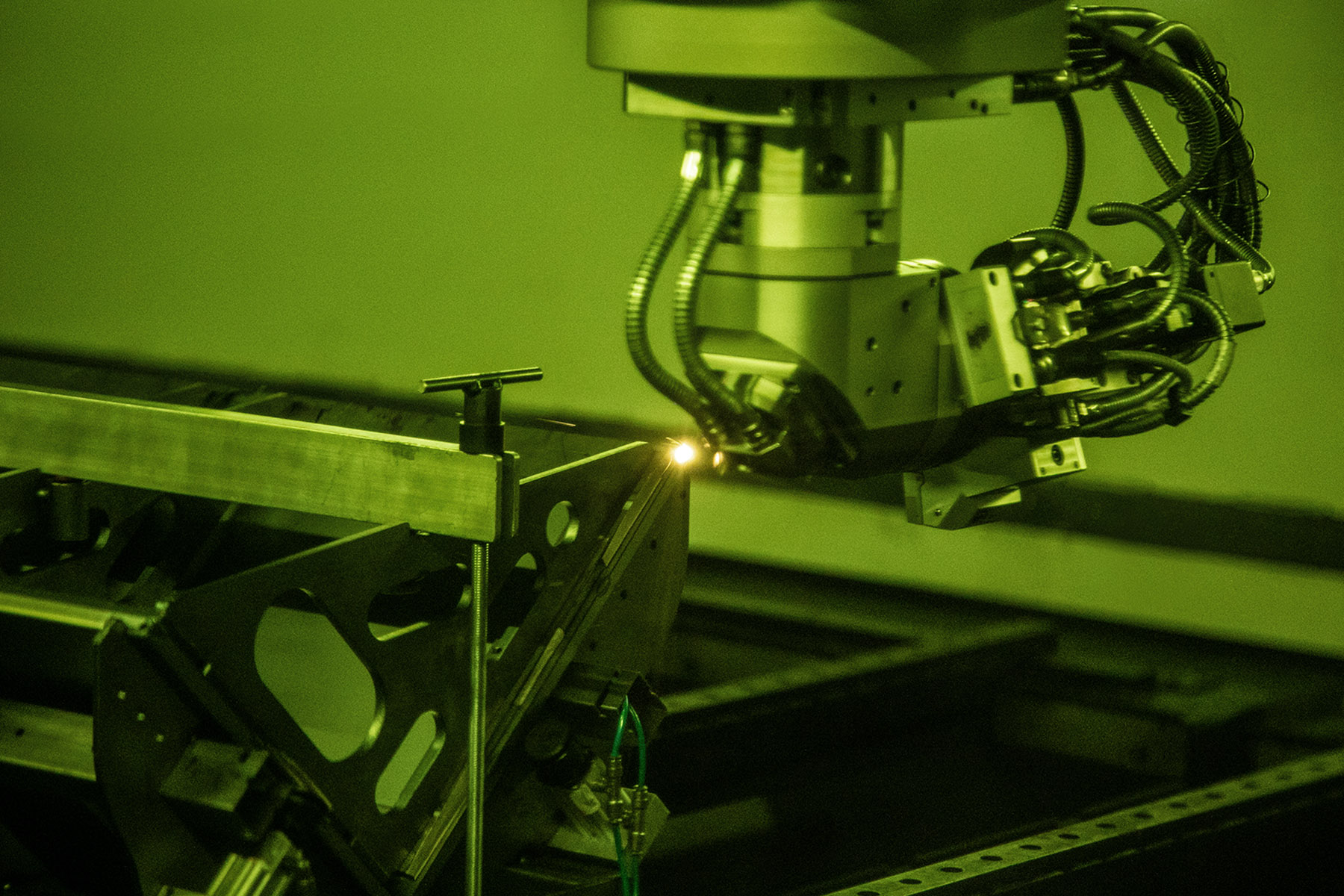

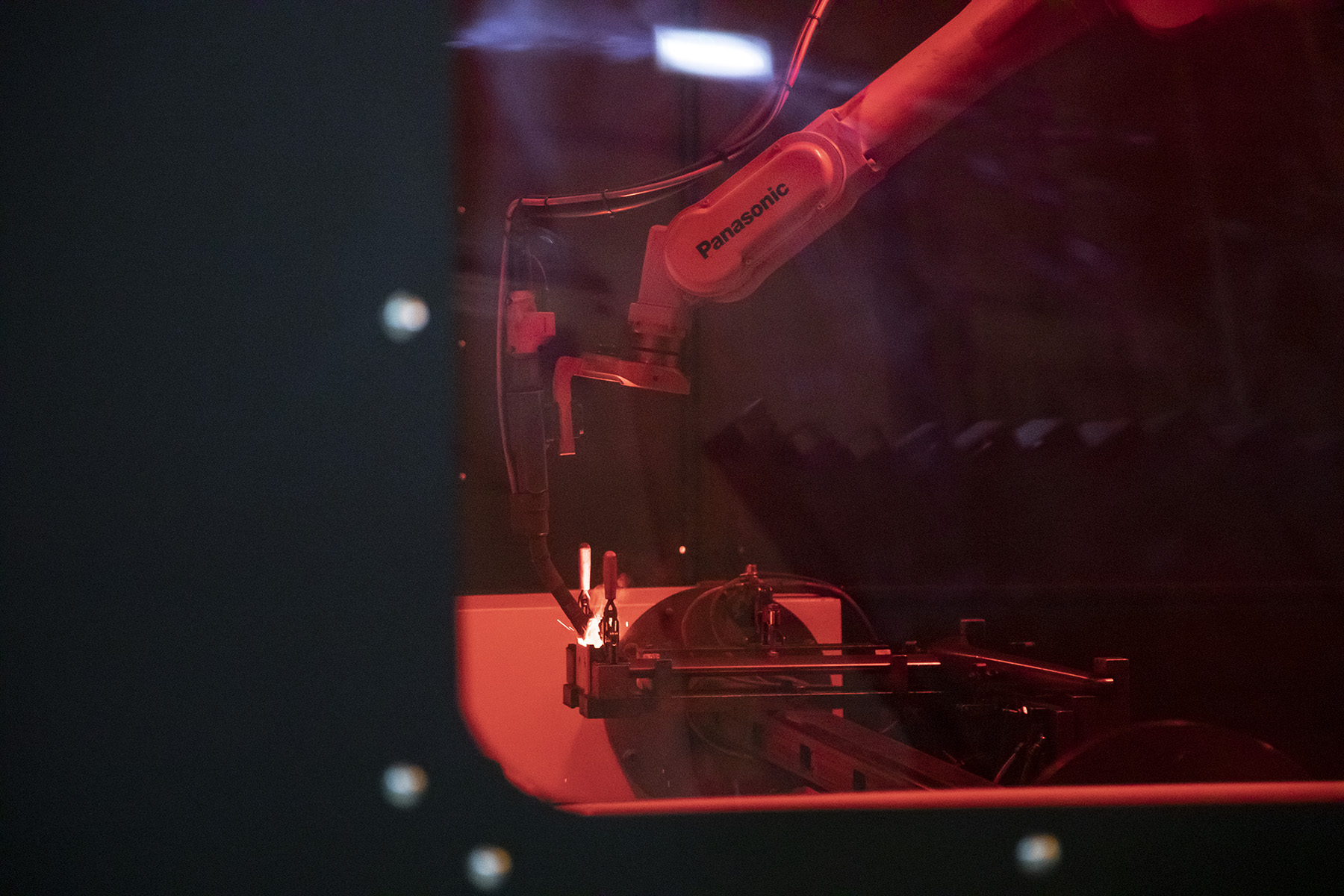

The new Laser Fiber Tube 7000 cutting system is capable of producing four times faster than the previous one and can reduce energy consumption.

We are an ISO 9001 certified company that produces in Italy using only quality raw materials. The entire production process takes place internally to ensure complete control of the timing, costs, and quality of the finished product. All our products are tested both internally, in a first phase, and at certified and authorized international bodies.

_Quality Total control of the production flow guarantees punctuality and quality

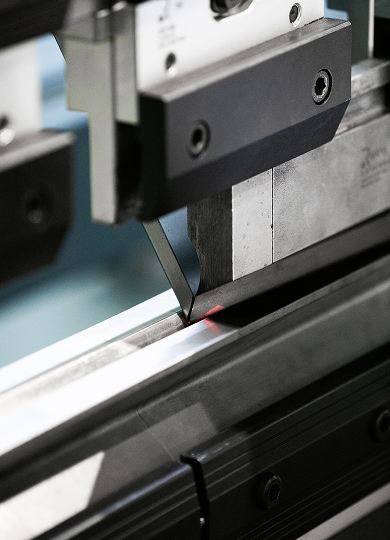

We use only the latest generation of machinery capable of producing products with impeccable and guaranteed quality.

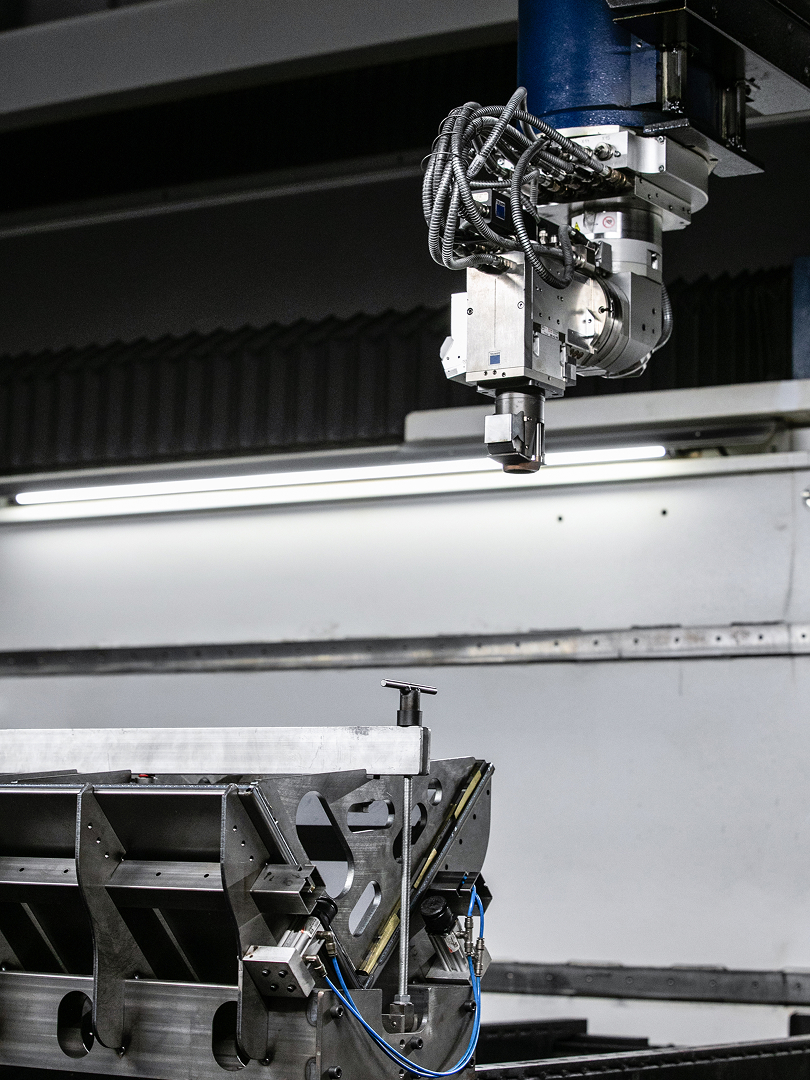

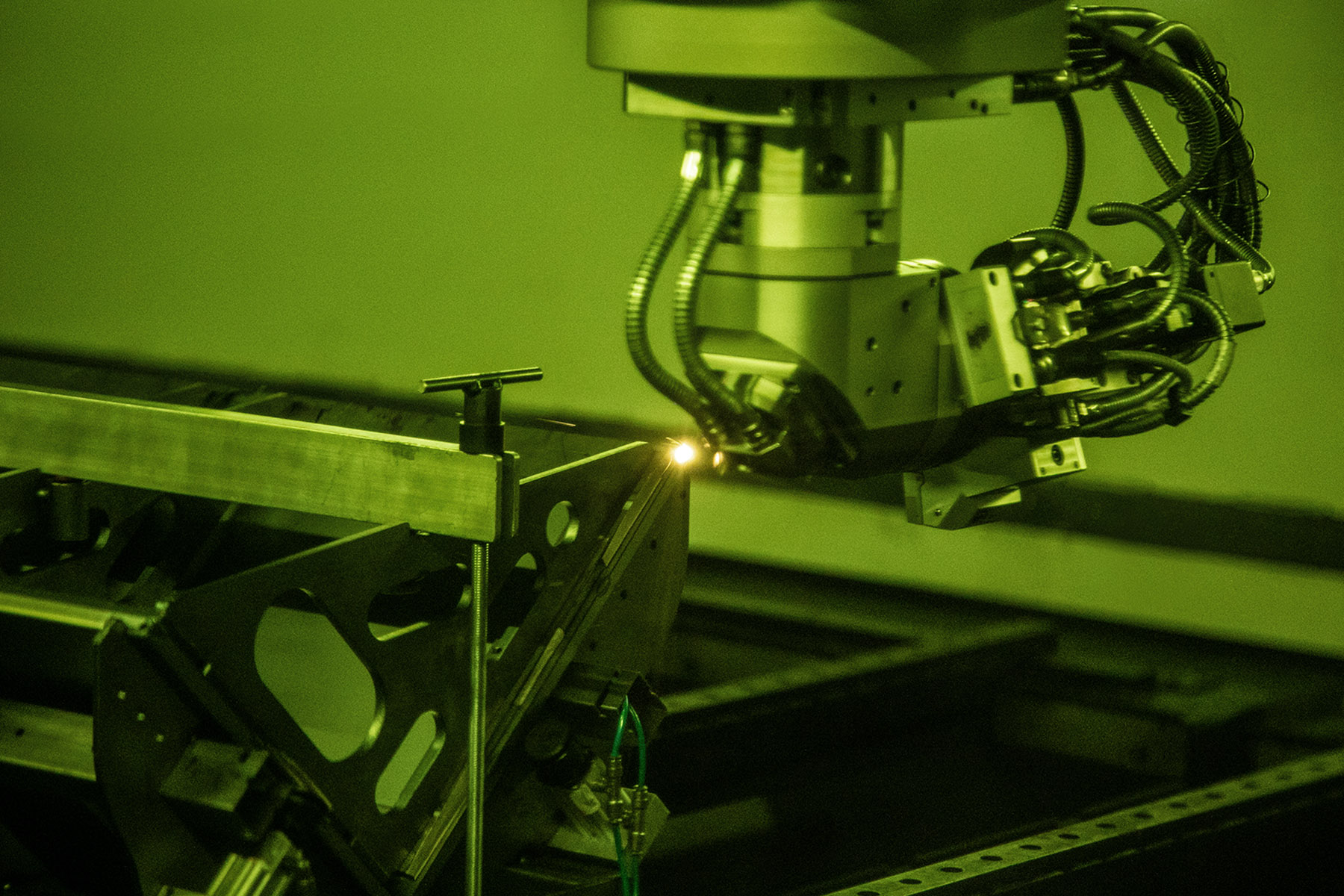

The new TruLaser Cell 7040 cutting system allows the cutting and welding of three-dimensional metal shapes. A futuristic machine so far used in the automotive sector that, in addition to offering new potentials in the world of design, is environmentally friendly thanks to the air channeling and filtering systems as well as the energy savings guaranteed by the fiber technology.

Painting is a very important process on which we pay attention to every detail. All products are verified by our operators through a thorough quality control within our 800 sq m painting plant.

The new automated painting plant, completed in 2025, is equipped with highly efficient final filters that allow to minimize material waste and energy consumption.