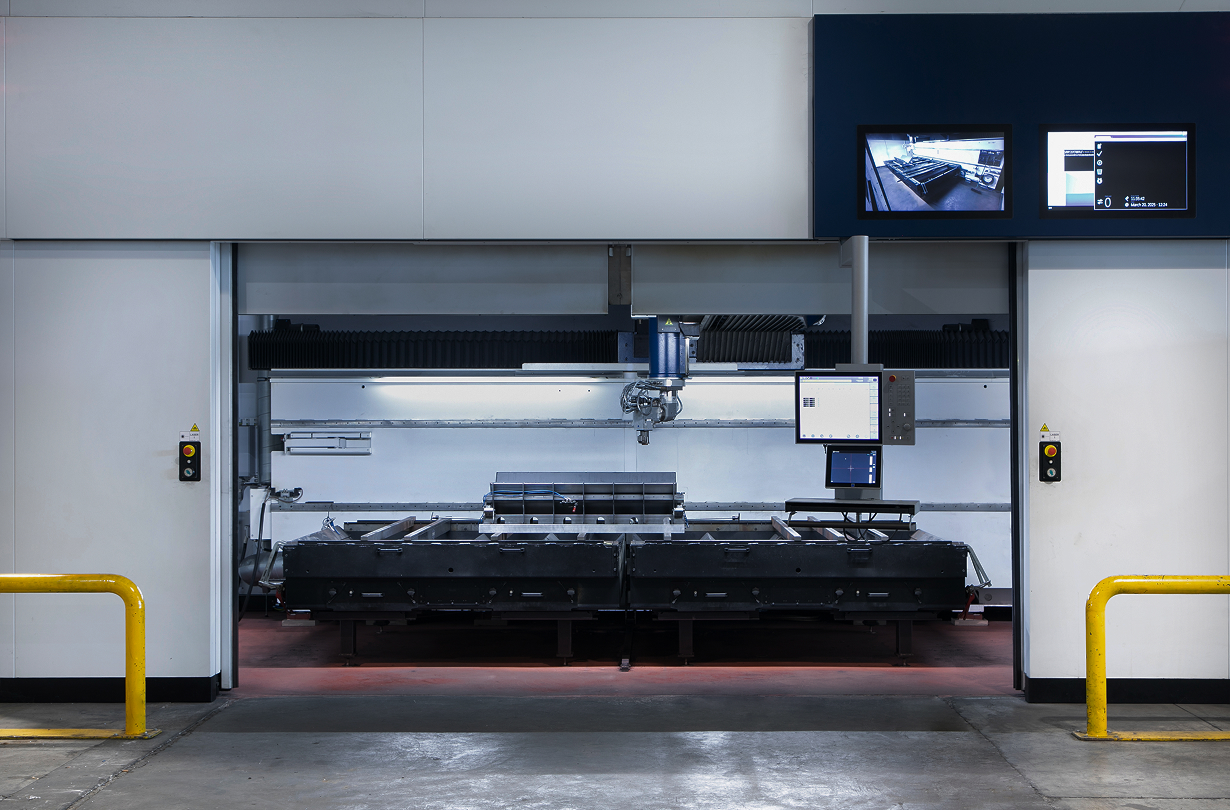

The innovative TruLaser Tube 7000 and TruLaser Cell 7040 Trumpf, with 2D and 3D CNC cutting and welding, used in production, are environmentally friendly thanks to the air ducting and filtration systems and allow high energy efficiency and minimal maintenance, guaranteed by fiber technology.

Sustainability A focus on environmental sustainability is a fundamental value.

Responsible management of energy, emissions, materials, and production methods represent a priority mission that we constantly implement.

For years, the company has undertaken a series of important sustainable investments and initiatives aimed at ensuring an environmentally responsible production that increases the use of recycled materials, reducing waste and the consumption of natural resources.

Towards a circular economy

Environmental sustainability is not a secondary objective, but a pillar of our industrial vision. We adopt practices aimed at reducing the environmental impact at every stage of the production cycle: from the choice of raw materials to production, up to the end-of-life of the products.

Concrete actions:

- Use of recycled and recyclable materials

- Reduction of waste and scrap

- Optimization of energy consumption

- Reuse and recycling as a production standard

Energy Sustainability

The atmospheric emissions of fumes from the various production plants comply with Legislative Decree 03/04/2006 n. 152, entitled “Environmental Regulations” which in Part Five “Regulations on air protection and reduction of atmospheric emissions” also governs the issuance of authorizations for atmospheric emissions for industrial plants and expressly repeals Presidential Decree no. 203 of 24/05/1988 and Presidential Decree 25/07/1991.

These evaluation criteria adopted are verified annually by a highly qualified and authorized research institute by the Ministry (D.M. 9.10.85 Law 46/82 Art. 4).

Environmental and Energy Sustainability

In 2024, we installed a new automated painting plant at our Brescia headquarters, powered exclusively by self-produced energy.

Results achieved:

- 90% reduction in powder waste compared to traditional systems

- High efficiency final filters according to UNI EN 16985:2019 standard

- Optimization of consumption thanks to frequency converters and intelligent automation

- Guaranteed safety and always available documentation (safety data sheets and powder analysis on request)

Energy Sustainability

Since 2021, we have embarked on a path of energy self-sufficiency based on renewable sources.

Results achieved:

- 511 kw of solar panels installed (2024)

- 124 kw of energy storage capacity

- 70% of the energy used in production is generated internally

- Progressive replacement of all electrical equipment with high efficiency and low consumption solutions

Environmental Sustainability

The woods used for the Mara collections are PEFC certified and come from responsibly managed forests. Upon request, FSC certified products can be provided.

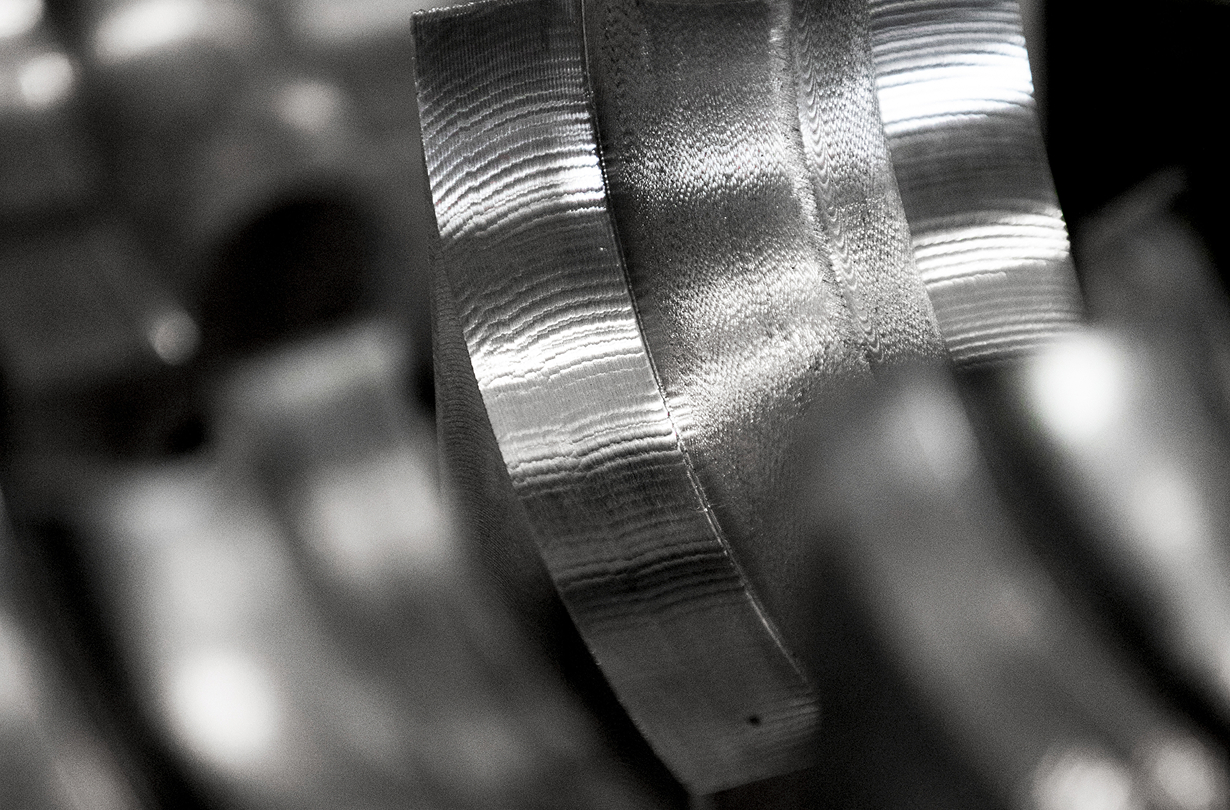

Local and traceable raw materials

The iron used in production for all products

comes from local steel mills.

The steel used is composed of 26% recycled content, 100% recyclable.

Less than 1% of our products contain chromated components, treated exclusively with Trivalent Chromium:

- Free of carcinogenic elements, unlike Hexavalent Chromium

- Does not generate hazardous waste

- Significantly reduces processing waste

- At the end of its life, the components are recyclable along with the steel

We believe in sustainable and long-lasting design. Our products are designed to be easily disassembled and recycled, minimizing the environmental impact at the end of their life.